A feature of the new shopping cart are improvements for the home page and the ability to show more images in the ads. I have decided to make use of a single cart to keep things simple, this shopping cart will allow me to carry both handwoven, and downloadable products at the same time. I also like to print and do illustration work, and likely you will begin to see a greater diversity in my product line. Hopefully, you will see something that catches your eye and think; Here is a way to support this artist.

I am beginning my 30th year of handweaving, and find I am not a true “hard core” academic (I may not have that laser focus). I love to teach and love working with people in general. I excel at small groups and one on one, solving problems as we weave together. I love to research and curate information about weaving especially in the 1700s to early 1900s. I want to be part of the solution to identify and keep handweaving history and technical information in the accessible in public domain as much as possible. But, at the same time software is not free, and web servers cost money to run. Keeping something alive will require a business model that generates supportable income in to the future after I am gone. I know that I do not have the physical strength/endurance or the time to be a production weaver, I am a designer at heart. I love to solve problems, and then I move on to the next problem.

With COVID-19 I lost my opportunity to demonstrate handweaving to the public by letting the new weavers try the looms for themselves, and have retreated into my studio. While being in the studio, I decided that I could once again concentrate on historic research and drafting of contemporary versions of old patterns. I discovered that many of the designs I had created earlier in my career were no longer accessible because of the software going out of production, or becoming so expensive you needed to be a production weaver to be able to afford it. I have been dedicating my free time to capturing what data I could from these drafts and I will be transferring them into a more usable format for future generations to enjoy. As I complete the task I will post them to the website. I can not list them for free, because I need to cover sample production and web hosting hosting costs.

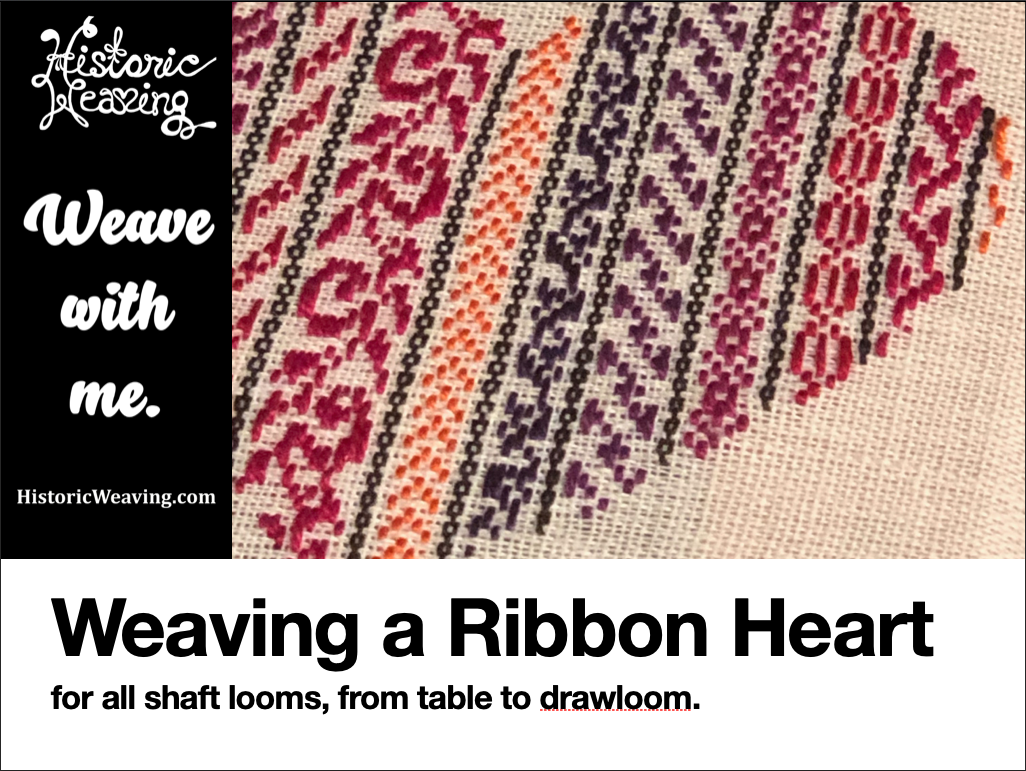

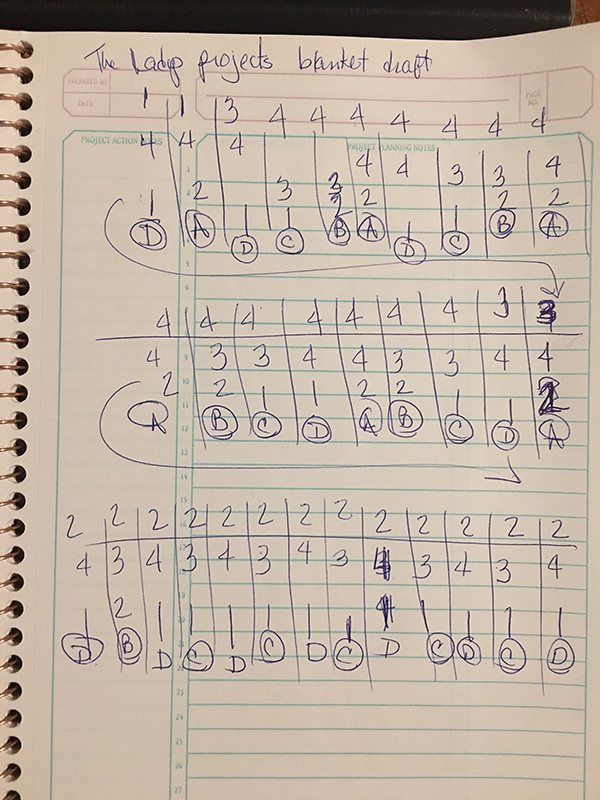

I have both 8 shaft looms, a computer-dobby 24 shaft loom, and a very large drawloom. I design for all three types of looms. In the shop I have decided to mark the number of shafts needed for a draft at the top of the description so as not to disappoint a weaver. You will know what you purchasing before you hit the download button. I also also elected to include weaving software files and manual draft files in the same draft archive packages so that people no longer have to choose one or the other.

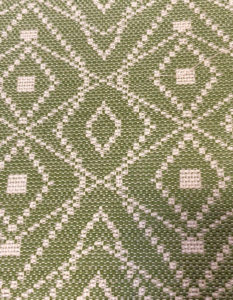

A few more words about the work I believe I can deliver to the public. I like to design drafts and weave it before I post it to ensure accuracy, but at this point some days I do more designing than weaving. I think I would like to work out a system with a fellow weaver(s), I would like to see I if can afford to pay a weaver to weave samples of these designs that I can post on the website and give credit for the work that was done. I have no worries if you determine that you would like to weave the design for production and sell items. I am aware that drafts can not be copyrighted, and so will not chase you down if you use a my design for sale in your shop. As I have mentioned before, it is not my intent to be a production weaver. If a weaver were interested in this type of arrangement, I would ask that you email me directly with what your financial requirements might be for making samples and what type of loom (mostly number of shafts) you are using for sampling. Sample sizes should be 10″ x 10″ or larger if the draft requires it for a full repeat. I am interested in high contrast samples so that it is clear to the weaver what is happening between the warp and weft threads.

For weavers downloading designs, please understand you are supporting my ability to create and maintain self sustaining a database of information related to weaving for access by yourself and other weavers. Downloading once and sharing widely with others defeats the business case for website sustainability. The drafts will have less value, and we all lose the resources we need to keep historic weaving documents and drafts available to the public. I also believe that I do not want to require a subscription to access the draft data or the learning that I have gathered. So this website will always have a public front end that is useful and full featured that is free.

I do not feel that I am in competition with sites like some international pattern libraries or handweaving.net. Historicweaving.com as a website predates them. I am not intending to scan books, or digitize a drafts in that way. I want to use the historic drafts to study how and why they were made, what makes them look the way they do, and how they can be modified to make new designs that reflect our time and current tastes. Understand my statement above that I am not a pure academic, who is driven to study the past and document it a completely as possible. I want to see the past, and bring it to back to life in an approachable way for today’s weavers and looms. My site will be different than others as I am different weaver. I have had this dream for a long time, and have spent that time learning about weaving and weaving software. I like to use Facebook as my studio blog, because Facebook can moderate comments faster and more safely. I want this expanded website for its database potential, and the ability to generate revenue to keep it self sustaining. I use Pinterest as a visual catalogue of ideas (a designer’s morgue file) to explore in the future. I’m learning how to write and present full digital content, some video, some pictorial, some e-books and stories. I believe we all learn in different ways and I want to explore ways to help other weaver’s pass on their notes/journals/drafts to the future as well. I have taken a few months to reflect on what I really want to do and how I want to spend my time. I want to research and to weave. (Ideally, I would like to travel as well, but that will take time and a vaccine.)

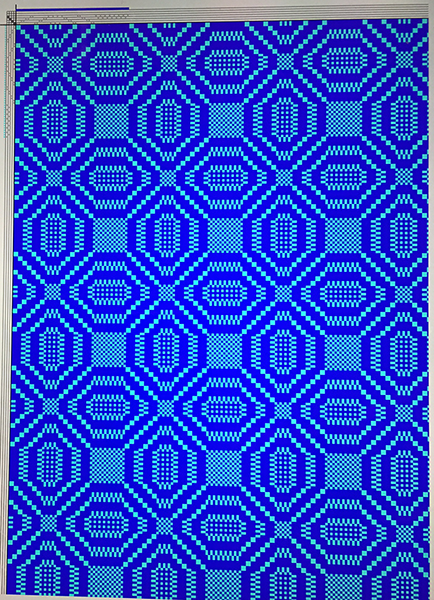

If I offer an handwoven item in my shop for sale it is most likely to be a one of kind – if it is not, the size of the edition will be stated. I have no desire to weave long warps of the same pattern. It slows me down once I have solved the design problem, I like to move on to the next. I like efficiency, but I am far more likely to want to achieve accuracy, especially in complex structures. I have been known to weave, unweave and rethread multiple times until I get the loom to match the draft. I spend more time finding ways to warp and weave better. I am known to innovate. If someone asks me how long it took to weave this particular item, it is hard to answer directly because I have to determine if should I tell you about all of the samples I made before I achieved success. (Again, note, I am not a production weaver). What will make my hand woven gifts special is you can be certain that you will not find another one just like it anywhere. When I use my looms I use them as close to their full capability as possible. My personal patterns are complex on purpose, I have a special hand loom, a 100 shaft combination drawloom and I like to show what it can do. To purchase a handwoven piece from me, pricing includes the cost of overhead for maintaining full weaver’s studio, time spent learning about weaving, the cost of materials and fact the item is unique. Your purchase dollars support my research efforts directly. I reinvest my profit dollars into the website and new weaving history research opportunities.

Now that you have heard more about my vision and process, let’s get to the good stuff – what did I add to the shop?

I began with creating an Illustrated Weaving Glossary meant for beginning weavers – https://historicweaving.com/wordpress/product/illustrated-weaving-glossary/ – never get confused about when a word is used and what it is referring to.

I have been researching extensively for the past couple of years Mary Meigs Atwater’s Shuttle Craft Guild – Lessons and her American Handweaving Book. Many of the documents I am working from are now in the public domain because their initial publication was 100 years ago, and are even more significant because they are her attempts to record information that was sent to her from other hand weavers throughout the United States. These items are truly meant to be preserved for the public because they came from the public. Since their initial publication, draft notation standards for these structures and patterns have changed significantly, usually it requires a bit of detailed reading to learn how to read the drafts from the manuscript.

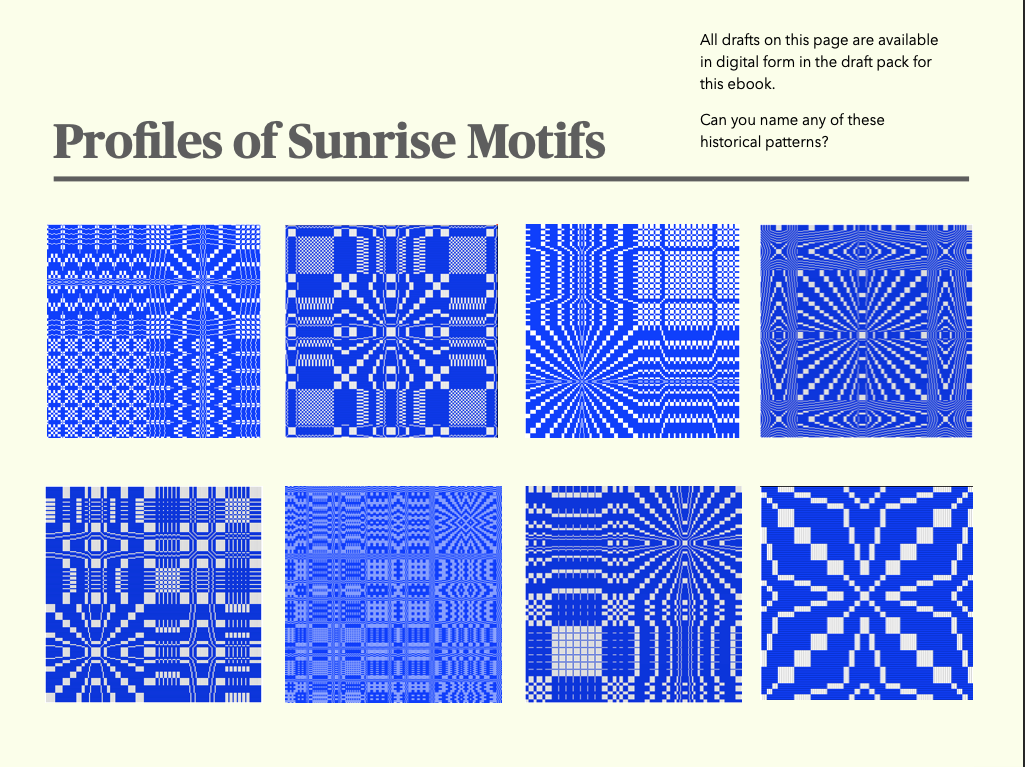

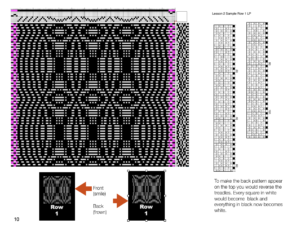

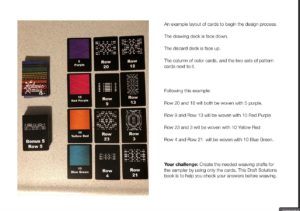

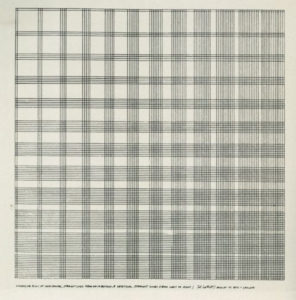

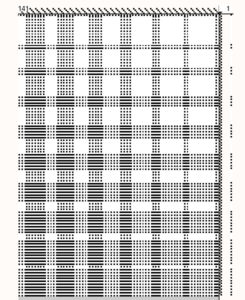

I have taken the time to record some of the larger coverlet radiating overshot pattern drafts in profile draft form making them more accessible to weavers who use drafting software. From the profile you can try different structures, colors and layouts to find a design that is pleasing to you. I have built instructions that show you how the draft is composed and how it can be modified. I would like to think of it as giving you design components more than a formal project plan. If you want the formal project plan approach use the Woven as Drawn in instructions. My goal in my presentation is to increase your understanding so that you can design your own projects and not not to restrict you to copying standardized patterns.

I added an eBook/PDF and draft package for Radiating Overshot Patterns – Sunrise, Blooming Leaf, Bow Knot and the Double Bow Knot. These designs include full drafts, profile drafts and woven as drawn-in drafts. This is the link to purchase the draft archive and the instruction ebook: https://historicweaving.com/wordpress/product/radiating-patterns-for-historic-overshot/

The Radiating Patterns ebook shows you how the drafts are related, the Draft Archive catalog details all of the profiles for easy reference to file names, and there are more than 68 drafts in the package. Included are the Lee’s Surrender, Sunrise and Blooming Leaf coverlets drafts. These drafts are the Series IV groups a,b,c and d – radiating patterns. From Mary Atwater’s original work combined with any examples I could find in digital museum collections that had no accompanying drafts with them.

Another bonus item from the American Handweaving Book, when published Mary Atwater made use of black and white photographs of historic coverlets she located in musuems. I have tracked the coverlets down and found color digital images from the current holding Museum’s digital collections. Use this link to download a copy of the original book manuscript and the link overlay to view the color images. https://historicweaving.com/wordpress/product/the-shuttle-craft-book-of-american-handweaving-updated-photo-links-in-pdf-format/

From the Mary Meigs Atwater’s Shuttle Craft Guild – Lessons, lesson 2 which concerns the Honeysuckle draft, I completed a copy of the Sampler Project that she requested as part of the lesson. That lesson encouraged me to create more than 50 unique treadlings to create the sampler assignment from Lesson 2, I named “Mournin’ Max” to honor the 100th anneversary of death of her husband Maxwell Atwater in 1919, an event that marked the beginning of her full time career in weaving that lasted for the rest of her life. Click on this link for the draft Archive. https://historicweaving.com/wordpress/product/draft-package-for-mournin-max-project/

Current research in the studio

Completion of the documentation of the reticule from the Montana Historical Society Museum. Can be woven on a 4 shaft loom. The structure is Honeysuckle Twill.

A welsh tapestry draft for a 24 shaft loom. Draft is complete, just needs weaving. (“Forget me Not”)

A contemporary version of the Lee’s Surrender draft, using a unit tie weave that can be woven on 6 shafts. In this archive there are colored versions of Lee’s Surrender as found in museum collections.

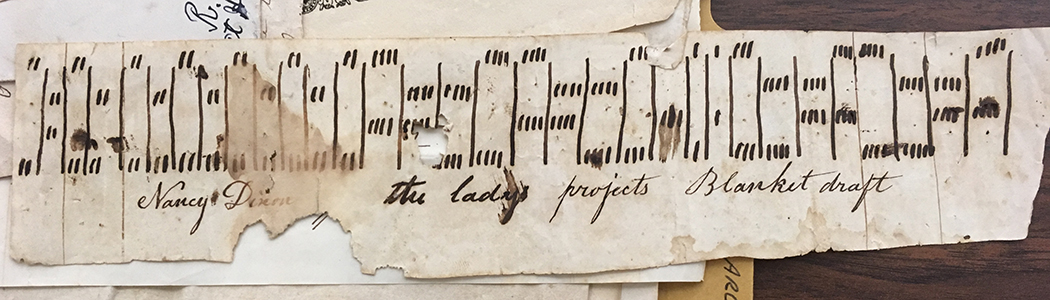

I am turning my attention to the weaver’s draft books in the United States in the late 1700’s how they got here and the influence they had. I have in my hands access to most of these books and some scholarly research to guide my efforts.

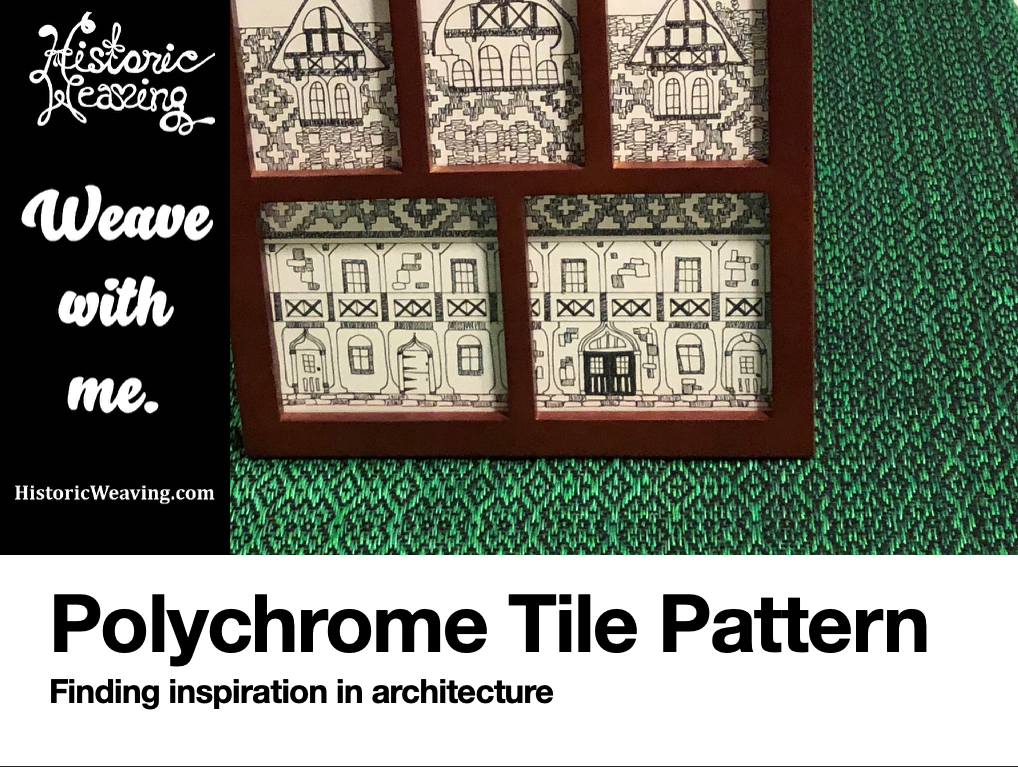

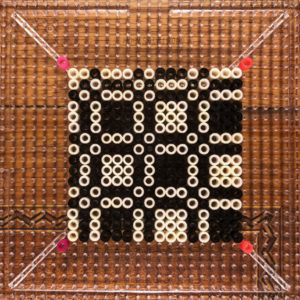

Also I am doing work documenting the drafts for the early Jacquard coverlet designs and determining what designs and motifs can be woven on conventional looms. Those that can not I will be using my drawloom to complete a sample of the designs for posterity.